Design and Construction

As funds trickled in, Bartholdi finalized the statue’s design. The plan placed a copper skin of 3/32nds of an inch thick over a wrought iron frame. The frame was crucial in keeping costs down and providing a strong support that proved flexible enough to withstand the constant wind that the statue would experience on Bedloe’s Island. For this, Bartholdi called on a young engineer Gustav Eiffel, who would later become world famous for his Eiffel Tower.

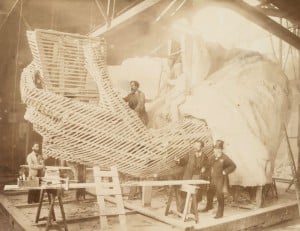

Construction of the skeleton and plaster surface of the left arm and hand of the Statue of Liberty, 1883. Courtesy of The New York Public Library.

Artisans constructed the representational copper skin through a labor intensive process, pictured at left, in which they built a full size wooden frame, after which they covered that frame with plaster, then created a wood impression of the plaster mold, and finally hammered copper sheeting against the detailed wooden mold. Ultimately, the statue consisted of over 300 copper sections, each uniquely numbered to guide the assembly.

Laborers used the funding that the Franco-American Union had collected to complete Lady Liberty’s torch bearing arm by 1876. The arm then traveled to America for inclusion in Philadelphia’s Centennial Exhibition.